- Montanuniversität Leoben, Chair wBw

- Software Competence Centre Hagenberg

- Messfeld GmbH

- BMW Motoren GmbH

- BRP Powertrain GmbH & Co KG

<< [ Back ]

Goal

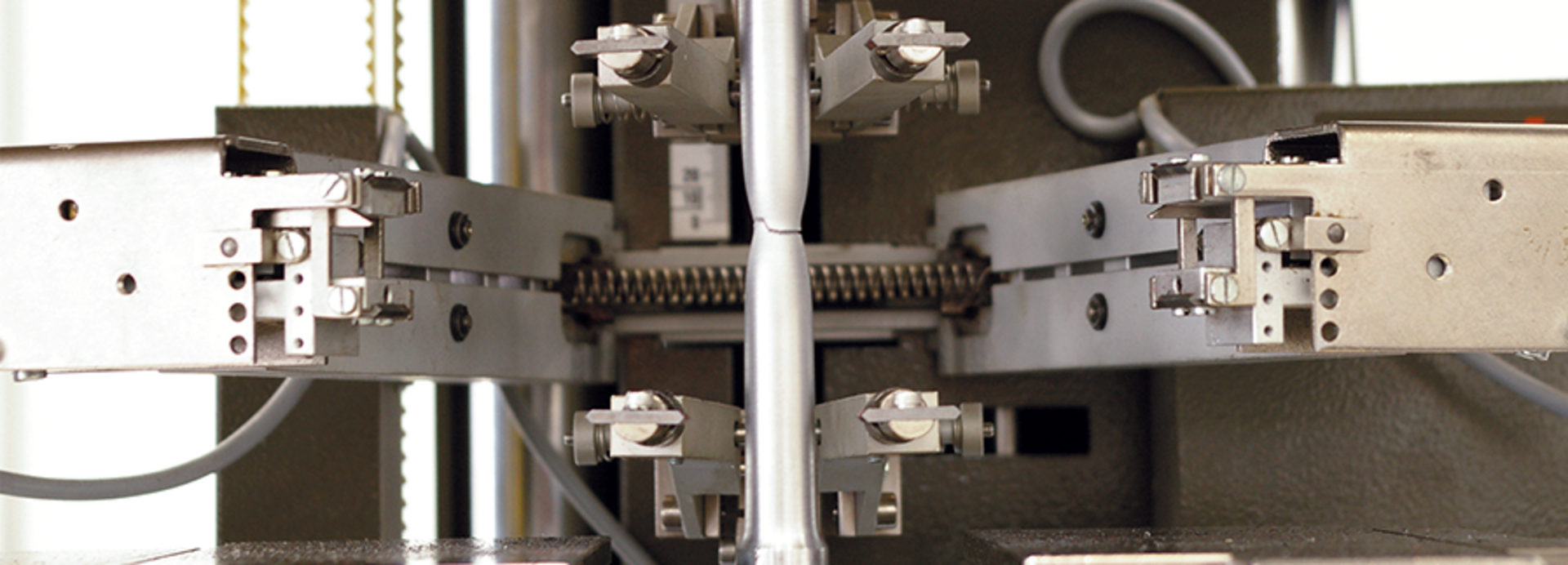

In the "Smart Maintenance" project, resource-intelligent, anticipatory maintenance is being developed using condition monitoring, data analysis and fault forecasting on the industrial partners' production systems and embedded in the maintenance strategy.

Benefit

New and known condition monitoring technologies are tested with regard to their techno-economic suitability. In addition, a fault prediction model is being developed from the production-related data. By conducting research on the production systems of the industrial partners, they benefit directly from the results obtained. The scientific community benefits from the publication of the findings in numerous publications.

Project content

As part of the RTI initiative (Research Technology Innovation) "Production of the Future", which is primarily dedicated to central issues in the manufacturing industry, the multi-year research project "Smart Maintenance" is being funded by the FFG. The aim of the project is to develop a resource-efficient maintenance approach. By combining mathematical, data- and knowledge-based, technological and economic methods, a model for improved maintenance strategy determination is being developed. The core topic is research into methods to improve the determinability of the failure behaviour of system components.

In addition to the technical realisation possibilities using the example of real production systems, the economic benefits of these newly developed methods are also examined and evaluated. The result for the industrial user is an increase in the availability and reliability of production systems, with lower maintenance costs at the same time.